Is It Possible To Analyze The Data From Two Cameras With Ncorr?

Abstract

Due to their cost, high-end commercial 3D-DIC (digital paradigm correlation) systems are still inaccessible for many laboratories or small factories interested in lab testing materials. These professional person systems can provide reliable and rapid full-field measurements that are essential in some laboratory tests with high-strain charge per unit events or loftier dynamic loading. However, in many stress-controlled experiments, such as the Brazilian tensile strength (BTS) test of compacted soils, samples are unremarkably large and neglect within a timeframe of several minutes. In those cases, alternative depression-cost methods could exist successfully used instead of commercial systems. This newspaper proposes a methodology to apply 2D-DIC techniques using consumer-form cameras and the open-source image processing software Dice (Sandia National Lab) for monitoring the standardized BTS test. Unlike most previous studies that theoretically estimate systematic errors or utilize local measures from strain gauges for accurateness assessment, we propose a contrast methodology with independent full-field measures. The deportation fields obtained with the depression-price system are benchmarked with the professional stereo-DIC arrangement Aramis-3D (GOM GmbH) in four BTS experiments using compacted soil specimens. Both approaches proved to be valid tools for obtaining full-field measurements and showing the sequence of crack initiation, propagation and termination in the BTS, constituting reliable alternatives to traditional strain gauges. Mean deviations obtained between the low-cost 2d-DIC approach and Aramis-3D in measuring in-plane components were 0.08 mm in the perpendicular direction of loading (ΔX) and 0.06 mm in the loading direction (ΔY). The proposed low-cost approach implies considerable savings compared to commercial systems.

Introduction

The Brazilian indirect tensile forcefulness (BTS) test is one of the most commonly applied testing methods for the analysis of brittle elastic materials such equally granitic rocks [1, 2], sandstone [three, 4], concrete [five, half-dozen], bituminous mixtures [7] and stabilized soil [8, 9]. Unlike direct methods, the BTS test submits disc-shaped samples to a compression line by loading two diametrically opposing points. In this manner, a tensile stress is generated within the cylindrical specimen until information technology fails. Failure is assumed to occur at the point of maximum tensile stress which should be located at the centre of the cylindrical specimen, co-ordinate to uncomplicated elasticity theory. However, detailed and accurate measurements of the deformation, strain values and points of failure are often required to obtain insight into the overall mechanical behaviour of the sample.

Traditionally, observation of the material deformation during lab testing was carried out by means of mechanical extensometers or strain gauges attached to the confront of the specimen. Gauges are typically placed vertically or horizontally to measure diametral strains [10] or across the crack oral fissure to monitor the opening deportation [11]. Even so, some previous studies have noticed significant differences in the strain measurements depending on the gauge size and the technology backside each device (eastward.g., conventional electric gauges, fibre-optic-based gauges) [12]. In contempo years, the utilize of digital image correlation (DIC) for the analysis of the displacement and strain of components in many types of tests has received particular attention [13]. Some studies, such as Sgambitterra et al. [fourteen], proposed reliable approaches using DIC for the evaluation of mechanical properties (Young's modulus, Poisson's ratio and tensile strength) of brittle materials during BTS testing. Other studies focussed on the application of DIC in BTS tests for monitoring crack initiation and propagation [15]. DIC's ability to capture data has led to a wide dissemination of this technique in the validation of BTS numerical models trying to understand the deformation behaviours in the full field [16] or more specifically in the fracture process zone [17]. In dissimilarity with traditional methods, DIC provides a continuous field of displacements beyond the surface of the specimen without the demand for direct contact. The principle of DIC is based on tracking the deformation of a random pattern over the surface of the sample during the test using a series of images taken by ane camera. The commencement image, normally taken before loading, is chosen every bit the reference image and serves as the origin for the displacements in the subsequent deformed images. Then, an automatic procedure of template matching is practical by the processing software in such a way that a pocket-sized reference region of the pattern (i.eastward., a correlation window), often chosen a subset or facet, is identified in both the reference and plain-featured images [eighteen]. In this simplest case, only two dimensions of displacements can exist calculated, and the strains of the fabric are assumed to be constrained to a plane parallel to the focal plane, as images from just one camera take been used (2d-DIC).

Consumer-grade cameras take been widely used instead of industrial cameras in different applications of ii-dimensional DIC, including lab testing of different materials [19, xx] and in-field applications at full calibration in large structures such as walls [21] or bridges [22]. Quanjin et al. [23] implemented a low-cost arroyo of second-DIC using consumer-course DSLR cameras and compared the results with strain gauges and with an experimental method. They obtained reasonably good understanding between them. Li et al. [24] also demonstrated the application of low-toll 2d-DIC with consumer-form DSLR cameras to make up one's mind the thermal expansion coefficients of materials, achieving accuracies comparable to industrial equipment. Zhao et al. [25] investigated the potential of low-cost 2D-DIC to analyse plastic shrinkage cracking on fresh concrete, where traditional methods of contact are non viable. However, information technology is also possible to estimate iii-dimensional deformations using two calibrated parallax cameras (stereo-DIC or 3D-DIC), thus enabling measurement of out-of-aeroplane displacements [26, 27]. This approach requires ii perfectly calibrated and synchronized cameras, which makes its application impractical virtually of the time unless commercial systems with specific binocular 3D systems are used [28]. Constructing a regular 3D-DIC system using two amateur cameras has some complexity, mainly because of the difficulty in accurately performing the internal and external orientations (which requires precise stereo calibration) and considering of the synchronization of the cameras. A common way to obtain synchronized photos has been the employ of mirror systems or optical prisms to capture in a single prototype the correct and left perspective of the object during the test [29]. This methodology has been successfully tested in performing different deformation measurements with a single DSLR photographic camera [30] and fifty-fifty using a single smartphone [31] with an optical attachment composed of mirrors. Despite this, 3D-DIC techniques using a single camera are generally limited to pocket-sized specimens with a size of a few tens of millimetres; otherwise, the overlap between diffracted or refracted images leads to decreased epitome quality [32].

There are a vast number of software packages and libraries, both commercial and open-source solutions that implement optical measurement techniques based on 2d-DIC or 3D-DIC to compute displacements from an image serial. Commercial systems, such as Aramis (GOM GmbH), StrainMaster (LaVision), Istra4D (Dantec Dynamics) and VIC-3D (Correlated Solutions), are also generally provided with their own specialized hardware and optical components (e.g., ultrahigh speed cameras for DIC, calibration plates, illumination systems). Although these high-end systems institute ready-to-utilise and very reliable solutions, their principal limitation is their inherent cost. Alternatively, the scientific customs makes available to users several open-source DIC programmes that tin be useful for many laboratories, small-scale factories, or research groups with more limited resources (eastward.g., MultiDIC [33], Ncorr [34], μDIC [35], py2DIC [36]). Some of these programmes are implemented in the MATLAB language, and so information technology is also necessary to purchase a licence [37]. Fortunately, there is as well space for open-source solutions such equally DICe (SNL, Albuquerque, U.s.) that can be directly run on most operating systems. Although the range of options for the user is varied, it is still difficult to brand comparisons with DIC from divide studies, as the assay parameters are addressed differently by each software package and even for the aforementioned test and using the same images, the concluding strain maps may look markedly different [38].

Previous studies have quantitatively evaluated the results of costless 2D-DIC software processing, some of them even in combination with amateur cameras. Nonetheless, the precision assessment of DIC systems is oftentimes based on theoretical estimation of systematic errors in local measurements or but on the determination of the racket floor. Few of the studies have set reference measures from which to quantify the errors, except directly measures from strain gauges. The problem is that the strain field gradients that occur during loading are hardly comparable with the local reads of strain gauges. Thus, an accuracy contrast methodology with independent full-field measures would exist desirable in those cases.

This article describes a procedure to perform full-field measurements of displacements during BTS testing using a 2d-DIC arrangement that combines consumer-grade cameras and open-source software (DICe). The aim is to investigate a reliable low-toll alternative for small labs to avoid the need to acquire commercial DIC equipment. A full of four BTS tests were performed to analyse the potential of the proposed depression-cost arroyo in monitoring compacted soil specimens during the standardized Brazilian test. The high-end commercial 3D-DIC system Aramis 3D, which integrates its own industrial cameras (12 One thousand) with a professional stereo-DIC processing module, was used to benchmark the functioning and the resulting full-field measurements of the low-cost system in terms of accurateness. It is important to emphasize that this is not just a comparison of software but of the systems equally a whole (i.e., optical systems and processing approaches); therefore, each system was used with its own images. Based on the performed experiments, general recommendations for conducting measurements in BTS testing are provided.

Methodology

BTS testing setup

There are several standardized procedures for applying the BTS examination to the measurement of tensile force, simply the most commonly used approaches are the ISRM [39] and ASTM [forty], both of which outline directly and indirect Brazilian test methods. Whilst traditionally the use of flat loading platens was adopted for BTS testing, further studies suggested that curved platens could be more than appropriate, merely to mitigate the burdensome effect of the loaded points, equally the elastic backdrop did not endure in principle any influence from the loading configuration [14, 41]. Therefore, the tests were performed by applying a compressive load at two points using curved breaking heads specifically designed to adapt the sample dimensions, thus preventing local compressive failure without significantly altering the tensile stress conditions. Although the loading rate has not previously been shown to take a significant effect on measured tensile stresses, it is assumed that lower ratios (i.eastward., < i mm min−one) produce greater repeatability than higher ratios [8, nine]. To achieve failure within a reasonable timeframe (within 1 to ten min), the loading in the ii experiments performed here was applied with a gradient of 0.ii–0.5 mm min−one. A motorized load frame S205N (MATEST S.p.A., Treviolo, Italia) was used to apply these constant rates of loading.

The soil specimens were prepared according to the process established in the UNE-13286:2011 [42] standard for the preparation of soil samples stabilized with hydraulic binders in laboratory testing. The specimens were compacted following the Proctor modified exam procedure using a type B mould of known volume, with a compaction energy of ii,586 MJ m−three and an optimum moisture content adamant from previous tests. Once compacted, the samples remain in the mould for 24 h in a humidity chamber for an adequate curing procedure. After this period, they are removed from the mould and stored until the test date under stable conditions of humidity (> 90%) and temperature (20 °C) in the humidity chamber.

The tests described in Sect. 3 were carried out using four dissimilar specimens: the first was composed of silty soil (ML in USCS classification) stabilized with 4% cement, and the other three specimens had an additional stabilizer (i.eastward., 4% of a biowaste rich in lignin obtained from the wood panel manufacture) [43]. The biowaste employed was a mucilaginous, chocolate-brown liquid rich in microfibres obtained past partial liquefaction of eucalyptus wood powder in deep eutectic solvents (DESs) and a subsequent process of decantation. The resulting product was a mixture of 26% pure lignin (16.5% Klaxon lignin/ix.47% soluble lignin) with ashes and sugars. Whilst the aim of the research is not to analyse the limerick of testing samples, the potential application of this blazon of industrial biowaste in soil stabilization is currently generating great interest [44, 45]. The properties of these specimens at the time of their elaboration are shown in Table one.

DIC testing setup

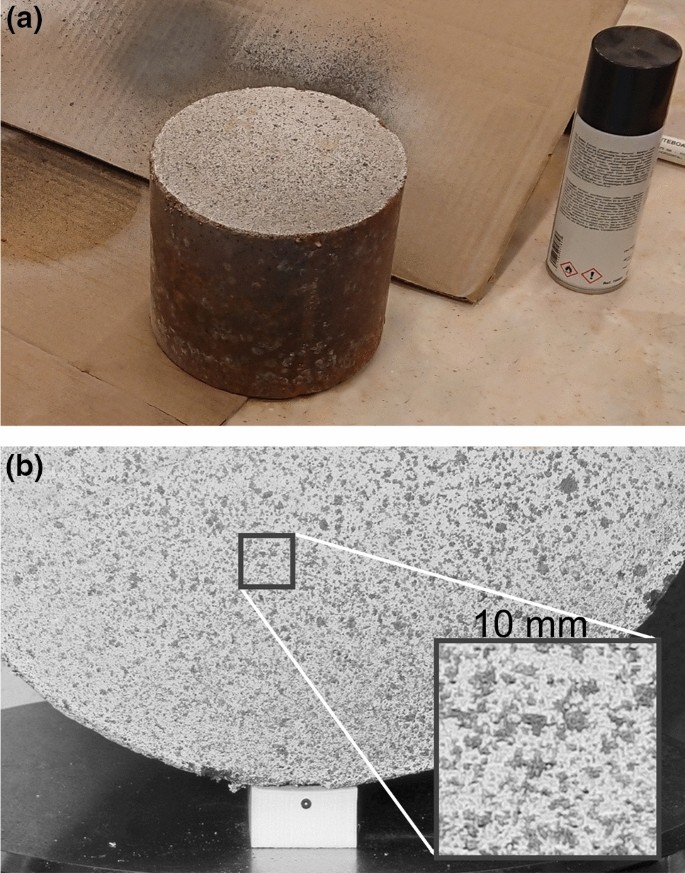

The final accurateness of DIC full-field measurements mainly relies on the capacity of the software algorithms to precisely place and track the deportation of small parts of the image forth the sequence of images. For that reason, the quality of the object texture is crucial to achieve an accurate match between the elements of the reference (first) image and the aforementioned elements in the deformed ones. Although some materials, such as natural rocks or concrete, may exhibit an inherent speckled design [46], the texture of the compacted soil specimens does not generally contain plenty identifiable features. In those cases, the greyscale values of the images may not be sufficiently stable to capture modest incremental deformations. Therefore, a black-on-white random speckle pattern (Fig. 1) was applied as uniformly as possible, using opaque spray paint on the plain face of each sample. A rigid pigment film over the face may change the mechanical stress atmospheric condition in the sample, and so it is very appropriate to use special paints for DIC that adhere to the surface simply deform easily with it. Thus, a professional acrylic spray enamel (Top Acrylic RAL ref. 9005 and 9010) recommended by the GOM's dealer was used (format 400 ml aerosol, drying 30–60 min, dry out movie thickness 13–fifteen microns according to ISO 2808 and gloss v–10 GE (matt) according to DIN 67,530).

Detail of the speckled blueprint: the application of a fine aerosol white coating followed by a spot distribution of black paint applied to specimens and the resulting b isotropic speckled pattern with an approximate 25–40% coverage

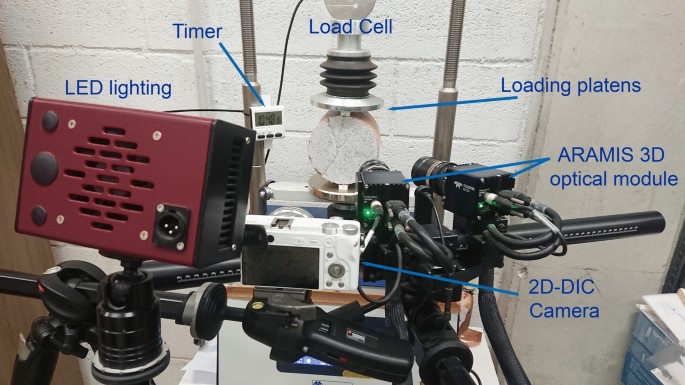

The experimental DIC setup was advisedly designed to simultaneously monitor the BTS tests with the stereo-DIC and the 2D-DIC low-toll system to brand comparisons. A Sony ILCE 6000 mirrorless camera (tests BTS-S1 and S2) and a DSLR Canon EOS550D (tests BTS-S3 and S4) were used in the tests, whilst data were simultaneously captured with Aramis 3D® (GOM mbH, Braunschweig, Germany) (Table two). Every bit second-DIC requires that the surface of the specimen exist positioned perpendicular to the axis of the camera, the optical module of Aramis (composed of two 12 M industrial cameras) was placed in an oblique position, which likewise allows it to record out-of-plan deformations. The placement of the Aramis optical module was also conditioned past the GOM's recommended distance to the specimen, varying co-ordinate to the calibration template used (in this case 295 mm) with an angle of 25.ii° betwixt cameras (typically, the stereo-angle should be betwixt approximately 15°–35° [47]). Despite being in an oblique position, the entire forepart face of the sample falls into the measuring volume estimated by Aramis in the calibration (195×160×150 mm of weight × height × field, respectively), ensuring that the depth of field is big plenty to have adequate focus over the surface of the specimen. In a like mode, the setup parameters of the consumer-grade cameras [i.due east., focal length, setup distance and field of view (FoV)] were selected together because all of them are intertwined and related to other parameters that are intrinsic to the camera (due east.g., CCD size). Cameras and lenses cannot exist selected independently due to the combined sensor size and lens effect on the resulting image scale. Yet, the position and setup of the cameras should exist prioritized for matching the desired FoV to the desired area of interest (AOI) [48]. Moreover, there are certain rules of thumb that should exist considered in 2d-DIC, such every bit avoiding very small focal lengths (<15°), to maximize the distance to the object and hence minimize errors acquired by out-of-plane movement. With this setup (Fig. 2), both DIC systems were confirmed to meet the overall recommendation of 2–thirty pixels per speckle in the pattern [4]. To ensure an acceptable brightness and contrast of the pattern [49], a common cold light LED source was also employed. The timers of all the cameras were synchronized prior to the experiments to make a precise adjustment of the image steps in the postprocessing phase. Every bit an additional check measure, a digital millisecond timer whose screen goes into the FoV of the cameras was introduced in the scene.

2D and 3D-DIC setup

Calibration procedure

DIC is a methodology with no inherent length scale, every bit the spatial resolution of the measurements varies with the characteristics of the speckled design, the resolution of the images and the established calculation parameters. This fact endows DIC with valuable flexibility to suit to the study of different types of specimens at different scales but besides poses challenges in scaling up the obtained measurements and determining its reliability.

In 2d-DIC, the only theoretical transformation required to catechumen the pixel space of the program to existent distance units is a scale factor. As this scaling process may be based on a unmarried measure, small errors in the distance determination could create large errors in the resulting displacements, and then an authentic reference, such equally a precision ruler or a calliper, should exist used. For this study, a precision ruler was introduced in the scene corresponding to the first (reference) image. The indicate grid resulting from the DIC processing is then scaled based on a distance measured over this ruler.

In contrast, the positions of the two cameras in 3D-DIC must be calibrated with respect to each other, so a single distance is no longer sufficient for the system scale. Thus, the mutual calibration process, start proposed by Zhengyou Zhang [50], involves the apply of a precision scale grid (typically a checkerboard or a dotted grid). The specific Aramis 3D calibration protocol includes an in-house calibration plate that allows for automatic detection of markers past the software post-obit the same procedure. A ready of several images of the calibration plate are obtained nether unlike orientations. The stereo-DIC software uses least squares equations to summate an authentic mathematical model of the sensor calibration, which includes camera positions and intrinsic parameters (e.grand., focal lengths, lens distortions, image centroids). The master do good of the calibration procedure performed in 3D-DIC is that the length scale of the images is accurately connected to the physical length scale of the imaging arrangement. In contrast, the scale of second-DIC is introduced past a uncomplicated and less accurate conversion between the pixel size of the images and the concrete size of the images.

Image acquisition and processing

Image acquisition is, in general, the most important stride in DIC, equally information technology is essential to have an appropriate set of images with enough quality to achieve reliable results. Therefore, it is essential to verify that the all-time-focussed area matches the AOI and to ensure an adequate level of illumination in the image. The consumer-grade cameras were both set up with a mid-range aperture of f/7.i, as the more extreme apertures are expected to introduce more distortions [48], and with an ISO of 100, equally increasing the gain increases camera noise. The Aramis software uses an internal protocol based on a calibration plate to correct the diffraction that allows precise adjustment of the aperture size, limiting motion blur and obtaining sufficient contrast. With these settings, parallel images were captured every 2 southward (0.5 fps) with consumer-grade cameras and Aramis-3D during the BTS experiments. The samples were loaded until the resulting fracture propagated through the whole specimen bore.

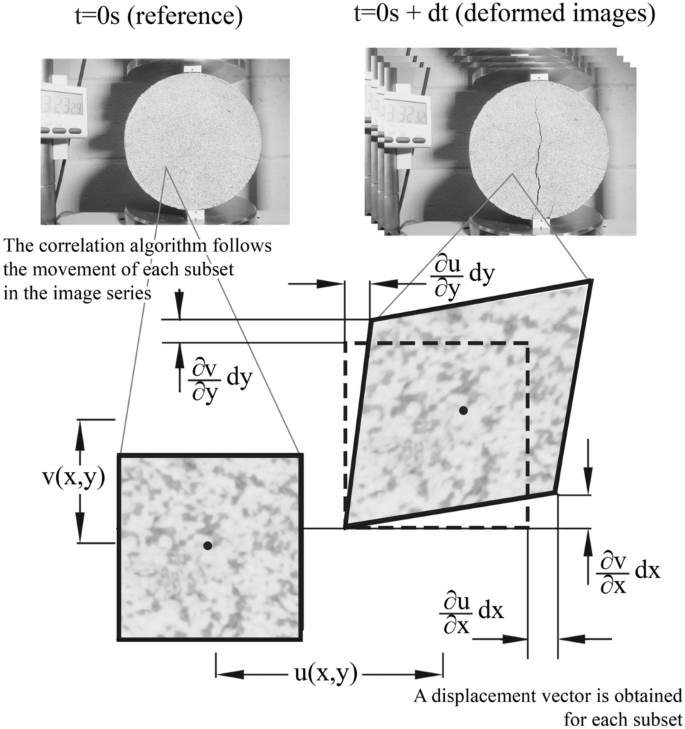

The 2D-DIC images were candy with the open up-source software Die, which is capable of computing full-field displacements and strains from a sequence of images (Fig. 3) [51]. In this example, outset-society shape functions, representing translations, rotations, normal strains and shear strains (Eq. 1–2), are used to locate an initial square subset in the reference image within the plain-featured images [52]:

$$\zeta i = u + \left( {\frac{\partial u}{{\partial x}}} \right){\text{dx}} + \left( {\frac{\fractional u}{{\partial y}}} \right){\text{dy}}$$

(ane)

$$\eta 1 = v + \left( {\frac{\partial v}{{\partial x}}} \right){\text{dx}} + \left( {\frac{\partial v}{{\partial y}}} \right){\text{dy,}}$$

(2)

where ζ1 and η1 are the full displacements of the subset; u and 5 are the translations; ∂u/∂x and ∂5/∂y are the normal strains; ∂u/∂y and ∂v/∂x are the shear strains; and dx and dy are the distances from the subset heart to an arbitrary indicate inside the same subset in the ten and y directions, respectively.

Fundamentals of 2d-DIC processing

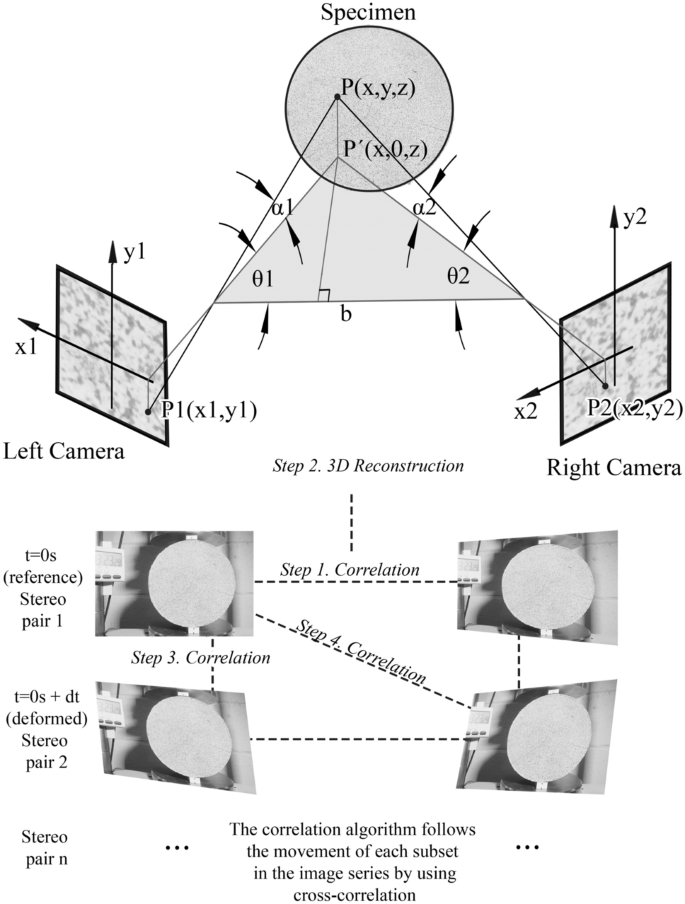

The calculation of the deportation maps from 3D-DIC is slightly more complex than from second-DIC, every bit DIC and stereo-vision principles are jointly involved in the transformation between epitome (two-D) and object space (3-D). Earlier calculating the 3D positions of each grid point, corresponding subsets should be located between the images captured by the ii cameras [53]. During this cantankerous-correlation, the perspective transformation from 1 camera to the other is matched past a shape function defined by the DIC software. This correlation process is equivalent to a 2D-DIC measurement in which the prototype from one camera (eastward.one thousand., left) is considered the reference image and the image from the other camera is the deformed image. In addition, as previously mentioned, the stereo calibration protocol provides the parameters needed for the reconstruction of the epipolar geometry, in other words, the intrinsic parameters (principal indicate, distortion parameters and focal lengths), the extrinsic parameters (camera poses) and the baseline of the stereo photographic camera organization [27]. This known stereo geometry constrains the search for homologous points between each pair of photos and allows for improved efficiency and amend accuracy in the matching process [54].

Once the respective points are located in the right and left images, the 3D position of the point of involvement tin can be computed based on the triangulation principle (Fig. 4). Considering a bespeak P with its corresponding projection on each image of the stereo pair [P1(X1, Y1) and P2(Xii, Yii)], the 3D coordinates can be derived from Eq. 3–5. This procedure tin can be repeated using a regular grid of points; thus, the 3D shape of the sample in the reference step (t = 0) tin exist obtained for the total AOI.

$$X = \frac{B \times \cot \theta 1}{{\cot \theta 1 + {\text{ cot}}\theta 2}}$$

(three)

$$Y = \frac{B}{{\cot \theta 1 + {\text{ cot}}\theta 2}} \times \frac{\tan \alpha 1}{{\sin \theta 1}}$$

(4)

$$Z = \frac{B}{\cot \theta ane + \cot \theta 2}$$

(5)

Fundamentals of stereo-DIC processing

The final analysis of 3D displacement vectors and the visualization of the respective maps are based on tracking the movement of the whole set of image subsets between consecutive images of the deformed states. The tracking algorithm uses cantankerous-correlation to discover the exact location of the subset in the next paradigm, and the deformation of the subset is considered using the shape function. This process allows u.s.a. to obtain the full field of displacements with a precision usually causeless to be less than i pixel due to the interpolation of the gray level values between image pixels. A more in-depth mathematical description of the calibration, cross-correlation, and dubiousness quantification, likewise as several awarding examples, can exist plant in references such as [55, 56].

In terms of use, DICe software is very attainable for DIC practitioners and beginners, equally information technology can run directly on the operating system and does not require programming knowledge. Despite performing the calculations, the Die software does not offer the possibility of directly representing the computed displacement maps and stress fields. An additional awarding such every bit Paraview [57] has to be used to open up the Exodus (*.due east) files for visualization and farther processing.

To obtain an optimized balance betwixt the spatial resolution and the interpolation error of the displacement fields, the values of the parameter subset size and step size were manually adjusted. The benchmark for setting the subset size value should be to choose a size large plenty for a subset to exist conspicuously distinguished from the other subsets. A rule of thumb in DIC is that each subset should contain at least 3 speckles with acceptable contrast [48, 58, 59]. Both Aramis and Die provide a preview of the result before performing calculations so that the user can check whether an increment in size is required to minimize empty areas (poorly correlated subsets in the AOI). On the other mitt, the step size or DIC point density defines the altitude between subsets, in turn influencing the spatial resolution of the measurements. Step size values are typically lower than subset size. It should be noted that the smaller the step size is, the greater the density of measurements and the longer the calculation time. However, a small step size is crucial for studying the differential behaviour of the cloth in the area near critical elements such every bit cracks. Following these criteria, values of 29 and 24 pixels were established for the subset size and pace size in DICe, respectively, and values of 19 and 16 pixels were used for the respective parameters in Aramis. Past using equivalent parameters in both systems, the analysis of the results could be simplified, obtaining directly comparable deportation profiles and maps with the same resolution. However, this would not reflect the actual level of accuracy achievable with each of the systems.

The whole front confront of the samples (~ 0.017 m2) was selected as the AOI for both 2D-DIC and 3D-DIC, obtaining an surface area big enough to ensure sufficient data for qualitative comparison of displacement maps. A grouping of 50 randomly distributed points along the AOI were selected in both the images of the conventional cameras and those of Aramis to evaluate the results quantitatively. This grouping of homologous points was used to compare the accuracy of the systems in performing measurements of the two in-plane displacement components and to estimate the error in the 2D-DIC depression-cost approach past omitting the out-of-plane movements.

Results and discussion

The four BTS experiments (S1–S4) were conducted post-obit the general procedures described in the standard UNE-EN thirteen,286–42:2003 [threescore] but with a modified head of the apparatus to suit specific dimensions of the compacted soil specimens, as described in Sect. 2.one. The geotechnical properties of the four samples and BTS test results are summarized in Tabular array 3. In all four experiments, a brittle failure style was observed every bit a vertical or near vertical tensile crack, and failure occurred within the starting time five min. The displacement maps were computed for each time step from the dataset of images taken during each of the four tests.

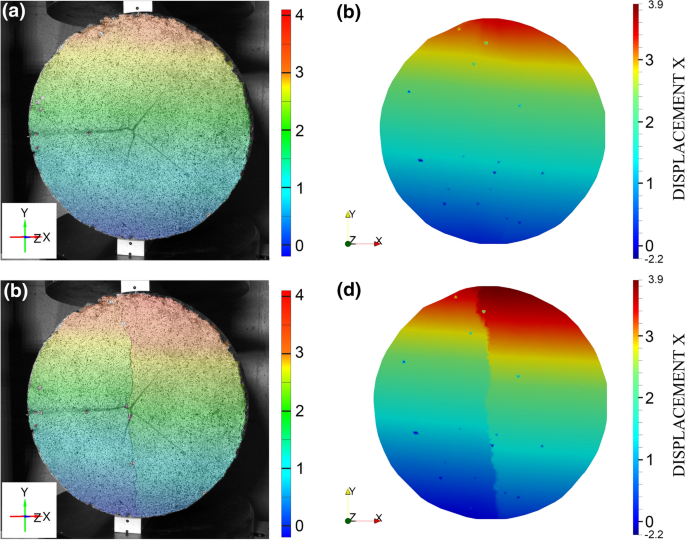

As illustrated in the full-field maps of Fig. five, the potential of DIC relies on providing a complete distribution of deportation information during the tests, in contrast to strain gauges, which but provide discrete information over an averaged area of awarding. With the setup and processing parameters established in the previous section, both systems provide in-plane displacement maps that are qualitatively very coincident. These maps let us to observe the global behaviour of the specimen surface throughout the whole test and to identify local phenomena due to cloth inhomogeneity and groovy at various levels (i.e., primary/secondary cracks). In that sense, both approaches proved to be valid tools if nosotros considered the requirement of DIC to bear witness the sequence of crack initiation, propagation and termination [61]. Plain, the exploitation of the results and further analysis options in the commercial software Aramis outperform the low-cost software, which lacks important features, such as the possibility to directly overlay the original image. Withal, most of these shortcomings can exist overcome after postprocessing using other visualization and analysis software such equally Paraview. On the other hand, the integration of acquisition and assay capabilities in a single product ensures that the data gathered with Aramis are handled quickly, being able to compute full-field maps of displacements and strains in nigh real fourth dimension. Information technology is too important to highlight that fifty-fifty when using a conventional DSLR or a meaty camera, DIC can produce a big amount of data during long recording times, which will significantly increase the postprocessing time. A couple of videos of the amateur 2D-DIC performance every bit a method for gathering the displacements during BTS tests are provided in the electronic Supplementary information.

Test 1. Displacement maps perpendicular to the loading direction before failure (t = 186 s) with a Aramis and b Die and after failure (t = 204 s) with c Aramis and d Die. Color scale equivalence is approximated

Some correlation artefacts can exist observed due to the lower quality of the design or its modification during the tests, particularly in specific areas such as the main cracks or previous marks on the face of the specimens. Small discontinuities in the total-field maps tin can usually exist interpolated without introducing too much fault, although this option has been disabled in this case to make them visible. These matching problems are perceptible in small areas of the GOM maps (Fig. 5a and c) only even more than evident in the instance of DICe (Fig. 5b and d), which presents discontinuities distributed all over the surface. These artefacts tin can locally distort the results, but the technique provides such a redundant number of measurements that information technology should not represent a problem to determine the global forcefulness parameters of the specimen.

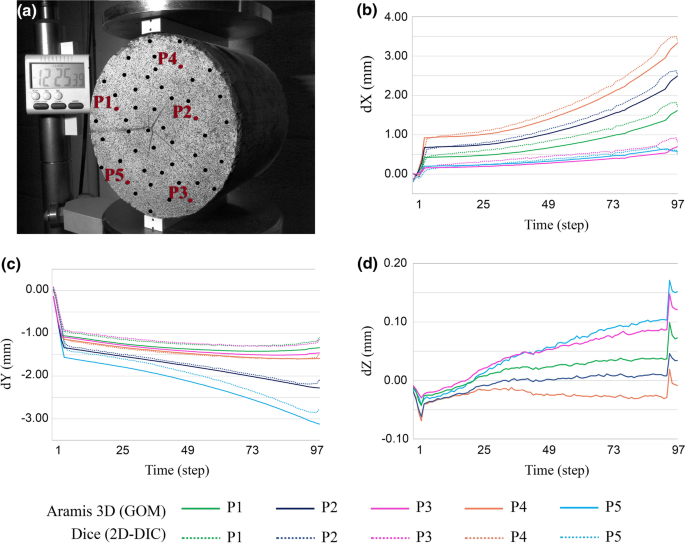

To compare the Die and Aramis results in a quantitative manner, the displacement values at 5 points on the surface of specimen S1 (randomly selected from the 50 total checkpoints) are too plotted in Fig. 6. The effigy shows a rather stable behaviour of the differences between the displacements measured with both systems, with a slight tendency to increase during the examination in the case of the deportation perpendicular to the loading direction (dX).

Displacement analysis in BTS-S1. a Distribution of checkpoints over the confront of the specimen. Magnitude of the displacements in the three components: b dX, c dY and d dZ obtained with Aramis 3D and Dice at v points on the specimen

Considering the whole prepare of tests (Table 4) and their entire footstep count, the mean deviations between Aramis-3D and low-toll 2D-DIC measurements ranged between 0.01 and 0.sixteen mm in the direction perpendicular to loading (ΔX) and 0.03 and 0.09 mm in the loading direction (ΔY). However, the comparative accuracy results between unlike tests should be read with circumspection, every bit some parameters of the optical systems (e.g., distance to object, prototype resolution, focal length) were configured independently for each test to keep the AOI constant. Moreover, other variables, such every bit the quality of the specimen'southward speckled patterns and the variable rate of loading, may accept a strong influence on the results. However, the results provide a full general idea of the order of magnitude of the errors using consumer-grade cameras for 2D-DIC. Given that the quality of the DIC measurements relies on numerous variables (due east.g., the camera-object distance, the size of the sensor, the lens, the quality of the speckle pattern), it would exist of interest to include a detailed clarification of all of these factors whenever this type of low-cost arrangement is used. In particular, it has been shown that the altitude to the object has a noticeable influence on the accurateness of the low-cost DIC. Therefore, information technology would also be good do to express the DIC error as a 1:d ratio, where d is the altitude to the object divided by the reported error. This yields mean values of ~ 1:5,100 for the experiments performed with the Sony ILCE 6000 at 525 mm (BTS-S1 and S2) and ~ 1:9,800 for the Canon EOS550D setup at 350 mm (tests BTS-S3 and S4). It should be noted that this metric (i.due east., relative fault) has no scale and is just a rough estimation of the truthful precision, which will vary within each paradigm step. Expressing the relative precision is ever a adept practice when optical methods are used, as the errors are more often than not highly dependent on the altitude to the object. However, the relative error does not replace the calculation of absolute errors from contained measurements.

As shown in the overall statistics for the BTS-S1 examination (Tabular array 4a) based on the fifty checkpoints, both in-plane deportation components are dominant in terms of social club of magnitude compared with the out-of-plane component. However, whilst a similar consequence applies to BTS-S2 (Tabular array 4b), the last two tests (Table 4c and d) show much larger mean out-of-plane displacements (up to iv mm). The variability in dZ when performing BTS tests is e'er difficult to control, as it depends to a great extent on the way the fracture occurs, the possible buckling of the specimen and other factors. Fifty-fifty modest variations in the initial positioning of the specimens or misaligned grips tin can lead to rotations or translations that will introduce meaning differences in the measured magnitudes. In 2D-DIC, a slight misalignment of the optical axis of the camera with the normal to the specimen surface can as well introduce a relative out-of-plane error, resulting in biased displacement data. Because the specimen is always assumed to be planar for out-of-plane motion in second-DIC, these displacements oft represent the largest source of error in the planar components [62, 63].

In that sense, stereo-vision systems offer a clear reward by allowing the joint analysis of the three spatial components. The analysis of checkpoints presented in Fig. 6d (BTS-S1) exemplifies the potential of 3D-DIC to capture fifty-fifty small movements and empathise the results (in this case, the lower part of the specimen seems to take shifted forward over fourth dimension until failure). However, the 3D-DIC organization involves multiple correlation runs, including cross-photographic camera subset matching, and requires the input of calibration data. According to previous studies, the eventual benefit of fugitive errors due to deviations from planarity can also introduce other error sources in the obtained deportation and strain fields [28]. This fact justifies to some extent why the results obtained in the measurement of the planar components do not show significant differences between Aramis-3D and the 2D-DIC low-toll system.

Conclusions

DIC engineering has experienced rapid diffusion in recent years in a range of laboratory tests, such as the Brazilian indirect tensile strength test, proving to be a reliable culling to traditional strain gauges. This experiment demonstrated that even a unmarried consumer-grade camera with APS-C sensors (size < 24 × 16 mm) that costs less than $1000 can exist useful in 2D-DIC setups for observing the fracture behaviour of breakable materials in experiments without loftier-strain rate events or high dynamic loading. The standardized BTS examination of compacted soil specimens works satisfactorily with the use of such cameras because the test elapsing is in general reasonably long (with speeds of approximately 0.2–0.v mm·min-1), and the use of loftier-speed industrial cameras is not strictly required.

Past using open-source software for processing epitome series, it is possible to extract basic qualitative DIC results as displacement maps that allow us to observe local behaviour phenomena during the BTS test due to material inhomogeneity, great, stress concentrations, plastic instabilities, and other characteristics. Moreover, the comparing of the results achieved in quantitative terms of accuracy shows trivial difference betwixt gratuitous 2nd-DIC and a professional 3D-DIC arrangement with mean values of approximately 0.06 mm in planar components (i.eastward., 1:5,000–1:10,000 of relative error at setup distances). More than specifically, the mean absolute deviations between Aramis-3D measurements and low-cost 2d-DIC were 0.08 mm in the direction perpendicular to loading (ΔX) and 0.06 mm in the loading direction (ΔY). However, since out-of-plane displacements caused by some effects that are difficult to control (e.one thousand., buckling, rotations, misalignment) reached mean values near 0.4 mm in some tests, they could accept a significant influence on BTS test results. For that reason, further research should also address the implementation of stereo-DIC with consumer-grade cameras.

References

-

Fourmeau Yard, Gomon D, Vacher R, Hokka M, Kane A, Kuokkala V-T. Awarding of DIC technique for studies of Kuru granite rock under static and dynamic loading, procedia. Mater Sci. 2014;3:691–7. https://doi.org/x.1016/j.mspro.2014.06.114.

-

Mardoukhi A, Mardoukhi Y, Hokka One thousand, Kuokkala VT. Effects of heat shock on the dynamic tensile beliefs of granitic rocks. Rock Mech Rock Eng. 2017;50:1171–82. https://doi.org/x.1007/s00603-017-1168-4.

-

Maruvanchery V, Kim E. Effects of water on rock fracture properties: studies of manner I fracture toughness, fissure propagation velocity, and consumed energy in calcite-cemented sandstone. Geomech Eng. 2019;17:57–67. https://doi.org/x.12989/gae.2019.17.ane.057.

-

Stirling RA, Simpson DJ, Davie CT. The awarding of digital image correlation to Brazilian testing of sandstone. Int J Rock Mech Min Sci. 2013;60:one–11. https://doi.org/10.1016/j.ijrmms.2012.12.026.

-

Mubaraki One thousand, Abd-Elhady AA, Sallam HEDM. Mixed mode fracture toughness of recycled tire rubber-filled physical for airfield rigid pavements. Int J Pavement Res Technol. 2013;vi:8–14.

-

Wang P, Gao N, Ji M, Stewart L, Arson C. DEM analysis on the role of aggregates on physical force. Comput Geotech. 2020. https://doi.org/ten.1016/j.compgeo.2019.103290.

-

Romeo Eastward. Two-dimensional digital image correlation for asphalt mixture characterisation: interest and limitations. Road Mater Pavement Des. 2013. https://doi.org/10.1080/14680629.2013.815128.

-

Akin ID, Likos WJ. Brazilian tensile force testing of compacted clay. Geotech Test J. 2017;40:608–17. https://doi.org/10.1520/GTJ20160180.

-

Stirling RA, Hughes P, Davie CT, Glendinning S. Tensile behaviour of unsaturated compacted clay soils—a straight cess method. Appl Clay Sci. 2015;112–113:123–33. https://doi.org/10.1016/j.clay.2015.04.011.

-

Erarslan DJ, Williams Due north. Investigating the effect of cyclic loading on the indirect tensile strength of rocks. Rock Mech Stone Eng. 2012;45:327–40. https://doi.org/10.1007/s00603-011-0209-7.

-

Erarslan Northward, Alehossein H, Williams North. Tensile fracture forcefulness of Brisbane tuff by static and cyclic loading tests. Rock Mech Stone Eng. 2014;47:1135–51. https://doi.org/10.1007/s00603-013-0469-v.

-

Yang YW, Bhalla S, Wang C, Soh CK, Zhao J. Monitoring of rocks using smart sensors. Tunn Undergr Space Technol. 2007;22:206–21. https://doi.org/10.1016/j.tust.2006.04.004.

-

Belrhiti Y, Dupre JC, Pop O, Germaneau A, Doumalin P, Huger G, Chotard T. Combination of Brazilian examination and digital image correlation for mechanical characterization of refractory materials. J Eur Ceram Soc. 2017;37:2285–93. https://doi.org/10.1016/j.jeurceramsoc.2016.12.032.

-

Sgambitterra E, Lamuta C, Candamano South, Pagnotta L. Brazilian disk test and digital image correlation: a methodology for the mechanical characterization of breakable materials. Mater Struct. 2018;51:1–17. https://doi.org/x.1617/s11527-018-1145-8.

-

Aliabadian Z, Zhao G, Russell AR. Fissure development in transversely isotropic sandstone discs subjected to Brazilian tests observed using digital image correlation. Int J Rock Mech Min Sci. 2019;119:211–21. https://doi.org/x.1016/j.ijrmms.2019.04.004.

-

Zhang H, Nath F, Parrikar PN, Mokhtari M. Analyzing the validity of Brazilian testing using DIC and numerical simulation techniques. Energies. 2020;13:1441.

-

Dutler Northward, Nejati K, Valley B, Amann F, Molinari G. On the link between fracture toughness, tensile strength, and fracture process zone in anisotropic rocks. Eng Fract Mech. 2018;201:56–79. https://doi.org/x.1016/j.engfracmech.2018.08.017.

-

Ravanelli R, Nascetti A, Di Rita M, Belloni V, Mattei D, Nisticó N, Crespi Grand. A new igital paradigm correlation software for displacements field measurement in structural applications. Int Curvation Photogramm Remote Sens Spatial Inf Sci. 2017;42:139–45. https://doi.org/10.5194/isprs-archives-XLII-iv-W2-139-2017.

-

Gauvin C, Jullien D, Doumalin P, Dupré JC, Gril J. Paradigm correlation to evaluate the influence of hygrothermal loading on woods. Strain. 2014;l:428–35. https://doi.org/10.1111/str.12090.

-

Phillips N, Hassan GM, Dyskin A, Macnish C, Pasternak E. Digital paradigm correlation to analyze nonlinear rubberband behavior of materials. Proc Int Conf Image Process. 2018. https://doi.org/x.1109/ICIP.2017.8297107.

-

Mojsilović North, Salmanpour AH. Masonry walls subjected to in-plane cyclic loading: application of digital image correlation for deformation field measurement. Int J Mason Res Innov. 2016;one:165–87. https://doi.org/10.1504/IJMRI.2016.077473.

-

Halding PS, Schmidt JW, Christensen CO. DIC-monitoring of full-scale concrete bridge using loftier-resolution wide-angle lens camera. In: Maintenance, safety, risk, management and life-cycle performance of bridges. CRC Press; 2018. https://doi.org/ten.1201/9781315189390-203.

-

Quanjin Grand, Rejab MRM, Halim Q, Merzuki MNM, Darus MAH. Experimental investigation of the tensile examination using digital epitome correlation (DIC) method. Mater Today Proc. 2020;27:757–63. https://doi.org/10.1016/j.matpr.2019.12.072.

-

Li C, Luo H, Pan B. High-throughput measurement of coefficient of thermal expansion using a high-resolution digital single-lens reflex camera and digital image correlation. Rev Sci Instrum. 2020. https://doi.org/10.1063/v.0013496.

-

Zhao P, Zsaki AM, Nokken MR. Using digital prototype correlation to evaluate plastic shrinkage nifty in cement-based materials. Constr Build Mater. 2018;182:108–17. https://doi.org/10.1016/j.conbuildmat.2018.05.239.

-

Chen F, Chen Ten, Xie X, Feng X, Yang Fifty. Full-field 3D measurement using multi-camera digital image correlation system. Opt Lasers Eng. 2013;51:1044–52. https://doi.org/10.1016/j.optlaseng.2013.03.001.

-

Yu L, Lubineau G. Modeling of systematic errors in stereo-digital image correlation due to camera self-heating. Sci Rep. 2019;9:1–fifteen. https://doi.org/ten.1038/s41598-019-43019-vii.

-

Wang P, Guo 10, Sang Y, Shao L, Yin Z, Wang Y. Measurement of local and volumetric deformation in geotechnical triaxial testing using 3D-digital image correlation and a subpixel edge detection algorithm. Acta Geotech. 2020;15:2891–904. https://doi.org/x.1007/s11440-020-00975-z.

-

White TG, Patten JRW, Wan KH, Pullen AD, Chapman DJ, Eakins DE. A single camera three-dimensional digital image correlation system for the study of adiabatic shear bands. Strain. 2017;53:i–11. https://doi.org/10.1111/str.12226.

-

Chi Y, Yu L, Pan B. Depression-price, portable, robust and high-resolution unmarried-photographic camera stereo-DIC system and its awarding in high-temperature deformation measurements. Opt Lasers Eng. 2018;104:141–8. https://doi.org/ten.1016/j.optlaseng.2017.09.020.

-

Yu L, Tao R, Lubineau G. Accurate 3D shape, displacement and deformation measurement using a smartphone. Sensors. 2019. https://doi.org/10.3390/s19030719.

-

Pan B, Yu L, Zhang Q. Review of single-camera stereo-digital image correlation techniques for total-field 3D shape and deformation measurement. Sci China Technol Sci. 2018;61:two–20. https://doi.org/10.1007/s11431-017-9090-x.

-

Solav D, Moerman KM, Jaeger AM, Genovese M, Herr HM. MultiDIC: an open-source toolbox for multi-view 3D digital paradigm correlation. IEEE Access. 2018;vi:30520–35. https://doi.org/ten.1109/ACCESS.2018.2843725.

-

Blaber J, Adair B, Antoniou A. Ncorr: open-source 2D digital paradigm correlation Matlab software. Exp Mech. 2015;55:1105–22. https://doi.org/x.1007/s11340-015-0009-i.

-

Olufsen SN, Andersen ME, Fagerholt Eastward. μDIC: an open-source toolkit for digital paradigm correlation. SoftwareX. 2020;11: 100391. https://doi.org/ten.1016/j.softx.2019.100391.

-

Belloni V, Ravanelli R, Nascetti A, Di Rita Yard, Mattei D, Crespi M. Py2dic: a new free and open source software for displacement and strain measurements in the field of experimental mechanics. Sensors (Switzerland). 2019;nineteen:1–xix. https://doi.org/10.3390/s19183832.

-

Belloni V, Ravanelli R, Nascetti A, Di Rita M, Mattei D, Crespi M. Digital image correlation from commercial to FOS software: a mature technique for full-field displacement measurements. Int Arch Photogramm Remote Sens Spatial Inf Sci. 2018;42:91–5. https://doi.org/x.5194/isprs-archives-XLII-2-91-2018.

-

Lunt D, Thomas R, Roy Grand, Duff J, Atkinson M, Frankel P, Preuss M, da Fonseca JQ. Comparison of sub-grain scale digital paradigm correlation calculated using commercial and open-source software packages. Mater Charact. 2020. https://doi.org/ten.1016/j.matchar.2020.110271.

-

ISRM. The ISRM suggested methods for stone characterization, testing and monitoring: 2007–2014. Cham: Springer; 2015. https://doi.org/10.1007/978-3-319-07713-0.

-

ASTM, D3967-xvi (2016) Standard test method for splitting tensile strength of intact rock core specimens. ASTM International.

-

Perras MA, Diederichs MS. A review of the tensile forcefulness of rock: concepts and testing. Geotech Geol Eng. 2014;32:525–46. https://doi.org/ten.1007/s10706-014-9732-0.

-

UNE-EN 13286-2 (2011) Unbound and hydraulically bound mixtures—function 2: examination methods for laboratory reference density and water content—proctor compaction. UNE standards.

-

Celeiro M, Lamas JP, Arcas R, Lores M. Antioxidants profiling of by-products from Eucalyptus Greenboards Manufacture. Antioxidants. 2019;8:263. https://doi.org/10.3390/antiox8080263.

-

Zhang T, Liu South, Zhan H, Ma C, Cai Chiliad. Durability of silty soil stabilized with recycled lignin for sustainable engineering materials. J Clean Prod. 2020;248: 119293. https://doi.org/10.1016/j.jclepro.2019.119293.

-

Yang B, Zhang Y, Ceylan H, Kim Due south, Gopalakrishnan Yard. Assessment of soils stabilized with lignin-based byproducts. Transp Geotech. 2018;17:122–32. https://doi.org/ten.1016/j.trgeo.2018.ten.005.

-

Sharafisafa K, Shen L, Xu Q. Characterisation of mechanical behaviour of 3D printed rock-similar material with digital image correlation. Int J Rock Mech Min Sci. 2018;112:122–38. https://doi.org/10.1016/j.ijrmms.2018.10.012.

-

Reu P. The art and application of DIC. Stereo-rig pattern: stereo-angle selection—office 4. Exp Tech. 2013;37:1–2.

-

IDICS. A good practices guide for digital paradigm correlation. Int Digit Image Correl Soc. 2018. https://doi.org/x.32720/idics/gpg.ed1.

-

Sciuti VF, Canto RB, Neggers J, Hild F. On the benefits of correcting brightness and contrast in global digital prototype correlation: Monitoring cracks during curing and drying of a refractory castable. Opt Lasers Eng. 2021;136: 106316. https://doi.org/10.1016/j.optlaseng.2020.106316.

-

Zhang Z. A flexible new technique for photographic camera scale. IEEE Trans Pattern Anal Mach Intell. 2000;22:1330–four. https://doi.org/10.1109/34.888718.

-

Chen L-C, Chang C-Y, Lee Due west-C, Ma C-C. Full-field measurement of deformation and vibration using digital image correlation. Smart Sci. 2015;3:80–six. https://doi.org/10.1080/23080477.2015.11665640.

-

Kasprzak B, Pękala J, Stępień A, Świerczyński Z. Metrology and measurement systems. Architecture. 2010. https://doi.org/10.1515/mms-2016-0028.Brought.

-

Zhong FQ, Indurkar PP, Quan CG. Three-dimensional digital image correlation with improved efficiency and accurateness. Meas J Int Meas Confed. 2018;128:23–33. https://doi.org/ten.1016/j.measurement.2018.06.022.

-

Hartley R, Zisserman A. Multiple view geometry in calculator vision. Cambridge University Printing; 2005.

-

Balcaen R, Reu PL, Lava P, Debruyne D. Stereo-DIC dubiousness quantification based on fake images. Exp Mech. 2017;57:939–51. https://doi.org/10.1007/s11340-017-0288-9.

-

Sutton MA, Matta F, Rizos D, Ghorbani R, Rajan S, Mollenhauer DH, Schreier HW, Lasprilla AO. Contempo progress in digital image correlation: background and developments since the 2013 Due west M Murray Lecture. Exp Mech. 2017;57:1–30. https://doi.org/ten.1007/s11340-016-0233-iii.

-

Ahrens J, Geveci B, Law C (2005) ParaView : an end-user tool for large data visualization, Tech Rep LA-UR-03-1. The visualization handbook. 2005; 717:viii:1–17.

-

Hu Ten, Xie Z, Liu F. Estimating grey intensities for saturated speckle to improve the measurement accuracy of digital image correlation. Opt Lasers Eng. 2021;139: 106510. https://doi.org/x.1016/j.optlaseng.2020.106510.

-

Dong YL, Pan B. A review of speckle design fabrication and assessment for digital image correlation. Exp Mech. 2017;57:1161–81. https://doi.org/10.1007/s11340-017-0283-1.

-

UNE-EN 13286-two (2003) Unbound and hydraulically bound mixtures part 42: test method for the determination of the indirect tensile strength of hydraulically bound mixtures. UNE standards.

-

He W, Chen 1000, Hayatdavoudi A, Huang P, Sawant Chiliad, Zhang C. Incorporating the effects of elemental concentrations on rock tensile failure. Int J Rock Mech Min Sci. 2019;123: 104062. https://doi.org/x.1016/j.ijrmms.2019.104062.

-

Sutton MA, Yan JH, Tiwari 5, Schreier HW, Orteu JJ. The effect of out-of-plane move on 2d and 3D digital paradigm correlation measurements. Opt Lasers Eng. 2008;46:746–57. https://doi.org/x.1016/j.optlaseng.2008.05.005.

-

Siegmann P, Felipe-Sesé L, Díaz FA. An alternative approach for improving DIC past using out-of-aeroplane deportation data. Opt Lasers Eng. 2020;128: 105996. https://doi.org/10.1016/j.optlaseng.2019.105996.

Funding

Open Access funding provided thanks to the CRUE-CSIC agreement with Springer Nature. This piece of work was supported by the Strategic Researcher Cluster BioReDeS funded by the Regional Government Xunta de Galicia nether the project Ref. ED431E 2018/09, by the Xunta de Galicia under the grant "Financial aid for the consolidation and structure of competitive units of investigation in the universities of the Academy Galician System (2020-22)" Ref. ED341B 2020/25 and past the Spanish Enquiry Agency (AEI) in the frame of the program Juan de la Cierva–Formación (Dr. Bastos) Ref. FJC2019-039743-I/AEI/10.13039/501100011033.

Author information

Affiliations

Corresponding writer

Ethics declarations

Conflict of involvement

The authors have no conflicts of interest to declare that are relevant to the content of this commodity.

Upstanding approving

This research does not business organization experiments involving humans and/or animals and does not require the approval of the ethics committee.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Supplementary Information

Below is the link to the electronic supplementary material.

Supplementary file1 (MP4 4516 KB)

Supplementary file2 (MP4 4239 KB)

Rights and permissions

Open Access This article is licensed nether a Creative Commons Attribution 4.0 International License, which permits apply, sharing, adaptation, distribution and reproduction in any medium or format, as long as you give advisable credit to the original writer(south) and the source, provide a link to the Creative Commons licence, and signal if changes were fabricated. The images or other 3rd party textile in this article are included in the article's Creative Commons licence, unless indicated otherwise in a credit line to the textile. If material is not included in the article's Creative Commons licence and your intended employ is not permitted by statutory regulation or exceeds the permitted employ, y'all will need to obtain permission straight from the copyright holder. To view a copy of this licence, visit http://creativecommons.org/licenses/by/four.0/.

Reprints and Permissions

About this article

Cite this article

Arza-García, M., Núñez-Temes, C., Lorenzana, J.A. et al. Evaluation of a low-cost arroyo to ii-D digital image correlation vs. a commercial stereo-DIC system in Brazilian testing of soil specimens. Archiv.Civ.Mech.Eng 22, 4 (2022). https://doi.org/10.1007/s43452-021-00325-0

-

Received:

-

Revised:

-

Accepted:

-

Published:

-

DOI : https://doi.org/10.1007/s43452-021-00325-0

Keywords

- DIC

- Brazilian tensile strength

- Stereo vision

- GOM

- Camera calibration

- Full-field measurements

Source: https://link.springer.com/article/10.1007/s43452-021-00325-0

Posted by: craighatiagoorah.blogspot.com

0 Response to "Is It Possible To Analyze The Data From Two Cameras With Ncorr?"

Post a Comment